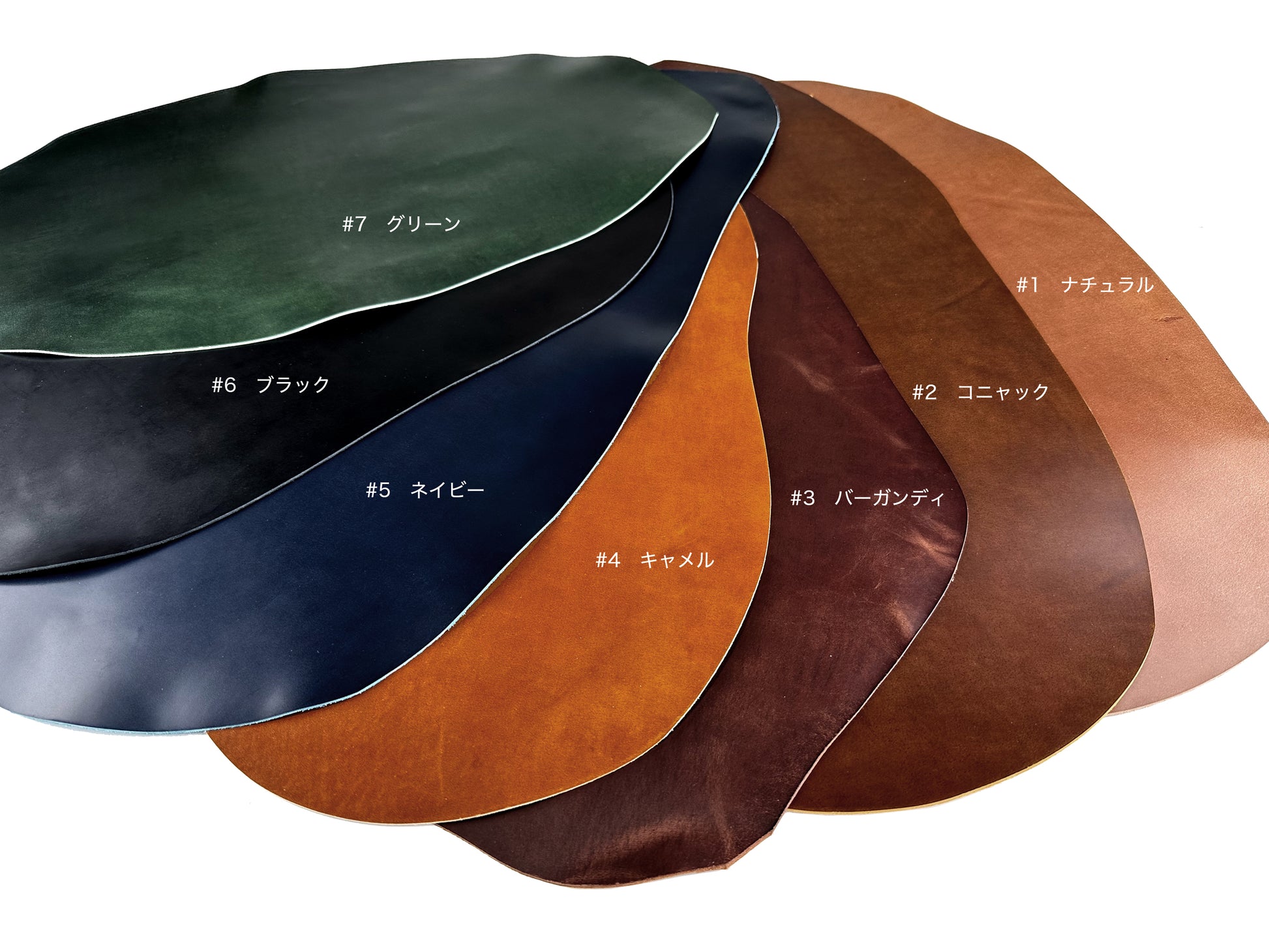

▼This image is a reference image and may differ from the actual stock.▼

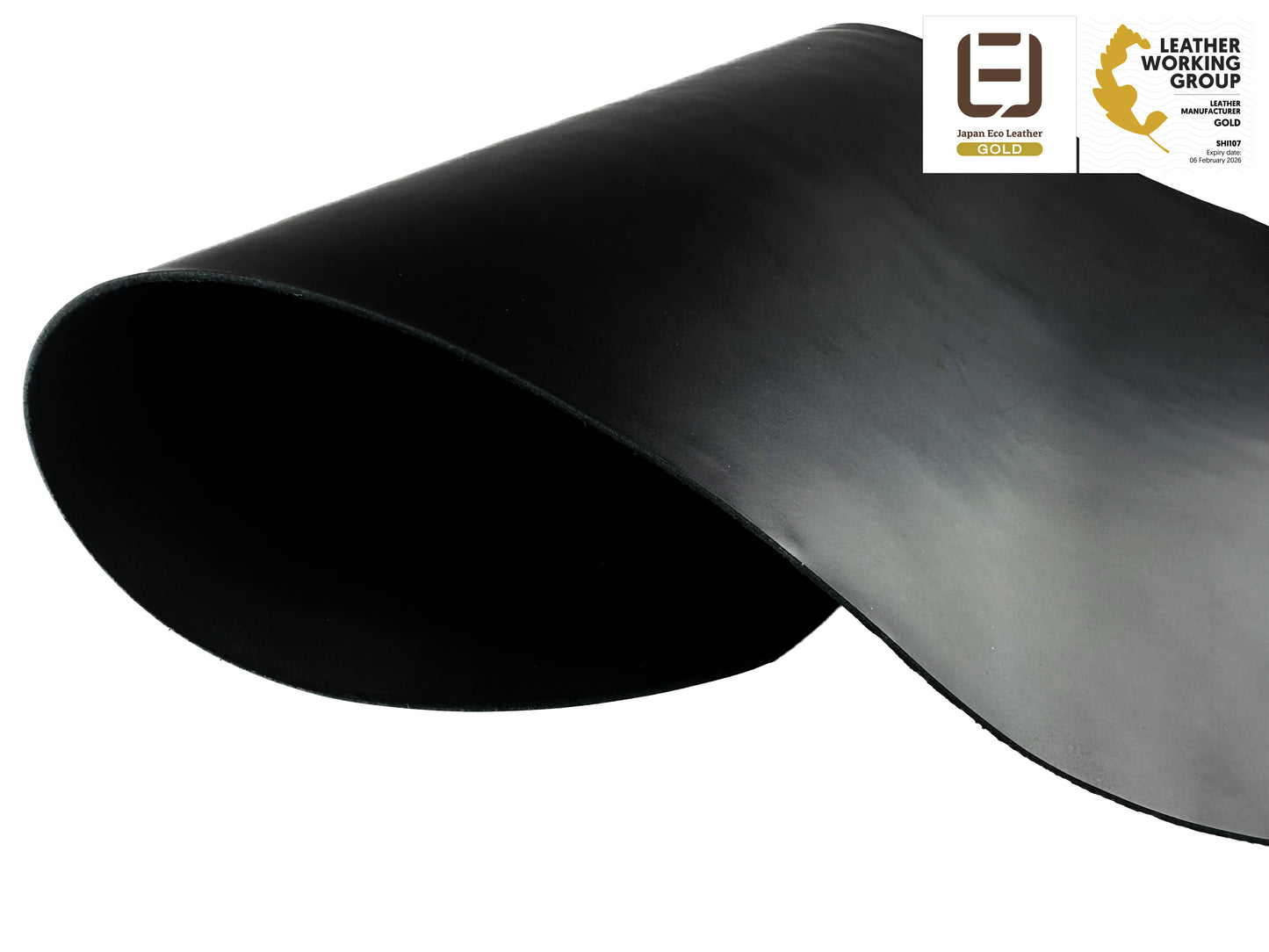

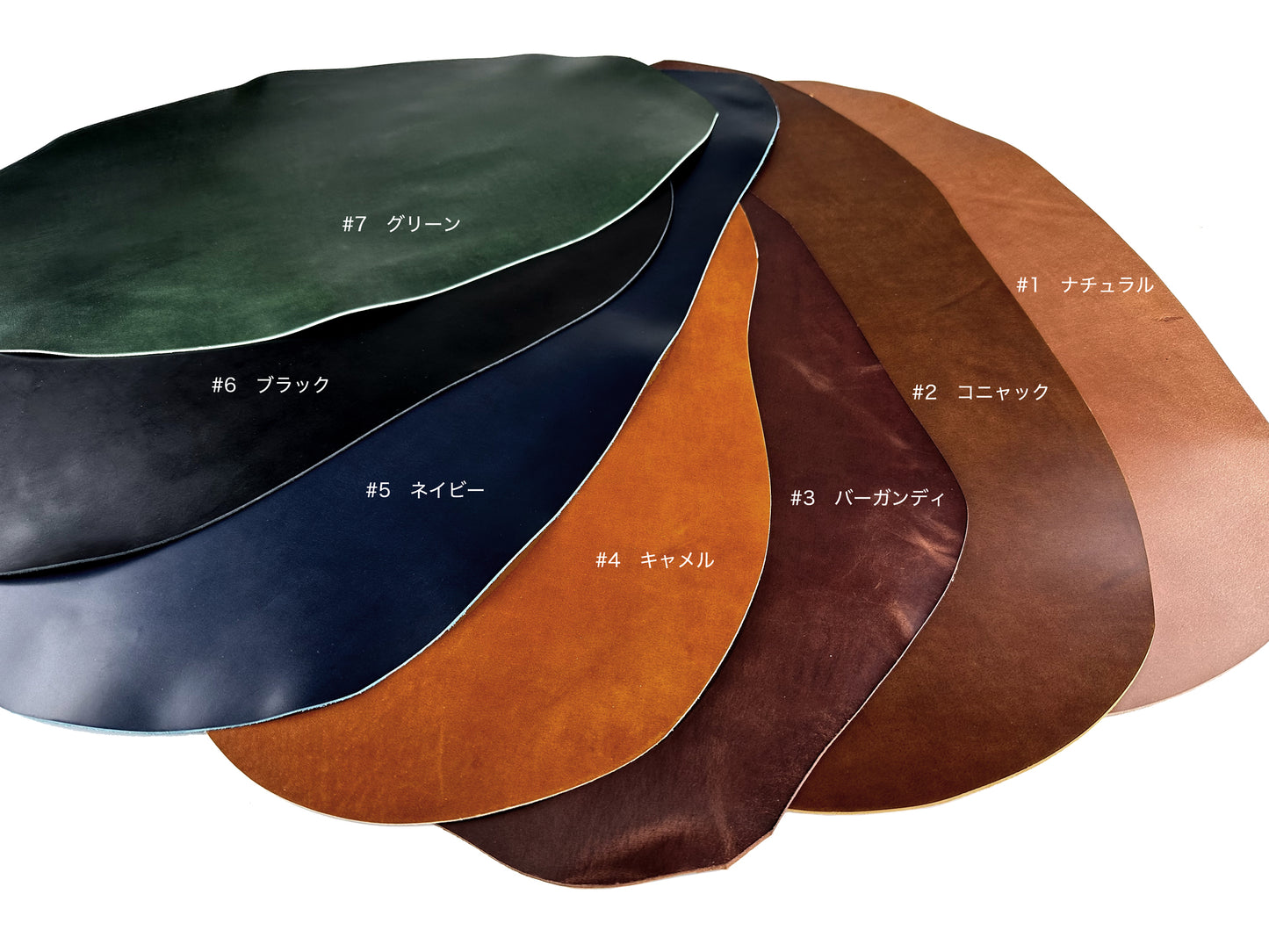

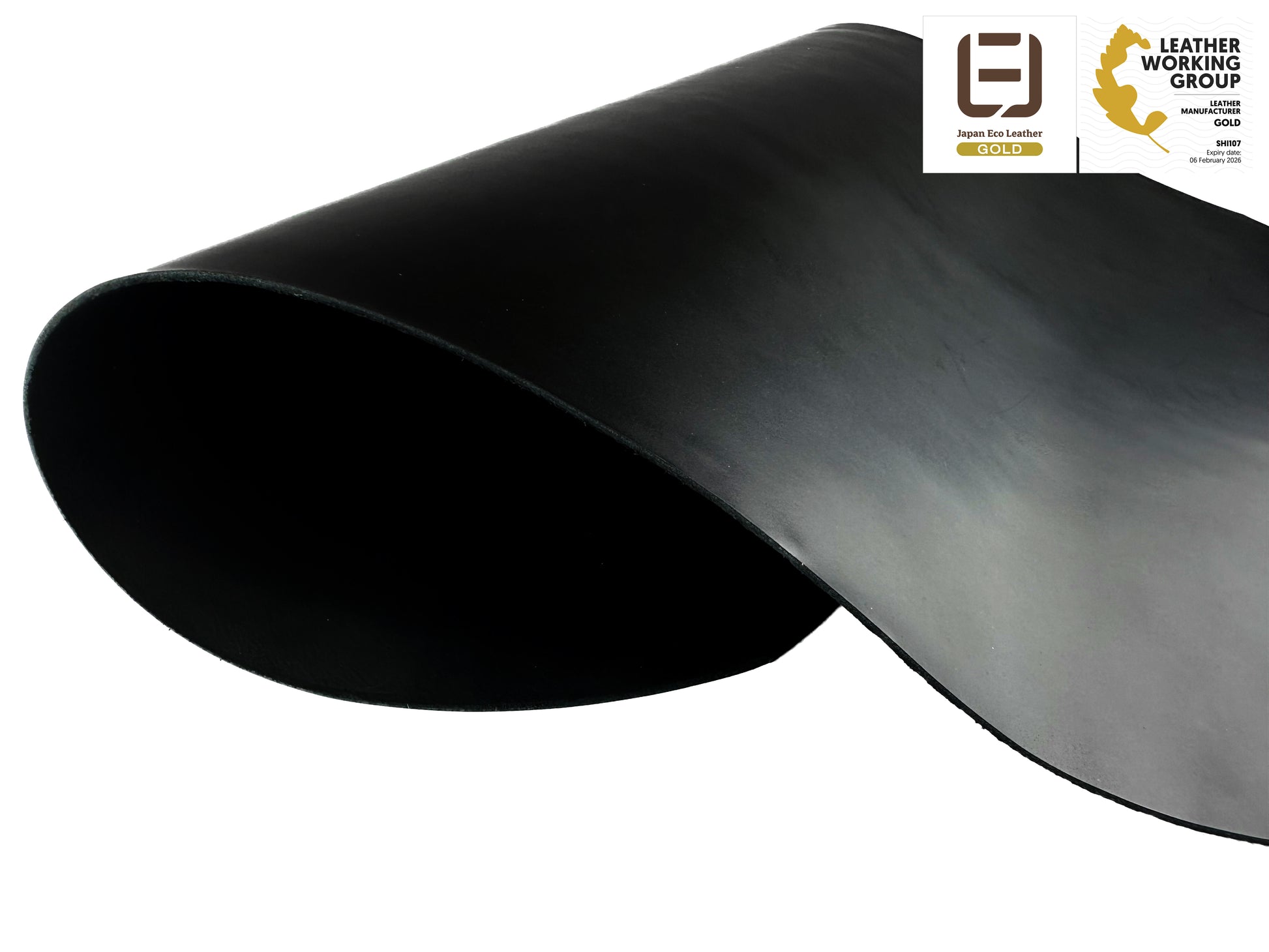

Shin Cordovan #6 Black

Shin Cordovan #6 Black

- Manufacturer:Shinki Hikaku

- Leather type:Horsehide(Hip)

- Thickness:1.0~1.8 mm

- ※Cordovan has different thickness depending on the part.

The actual thickness is listed in the stock list. - Unit Price:¥1,190

- Finishing:Dyed finish

- Texture:Smooth

- Type:Vegetable tanned

- *Prices may be revised without notice due to changes in raw material prices.

- *Leather has individual differences in thickness.

Tax included.

About stock

The inventory of the Fukuoka office is listed. Products displayed as sold out may be in stock at other offices, so please contact us using the inquiry form.

Couldn't load pickup availability

Oil cordovan, loved around the world

Since its founding, Shinki Leather Co., Ltd. has been researching and honing its technology for over 40 years, and has succeeded in producing and continuing to supply world-class cordovan .

In recent years, the price of horse hides has been rising sharply for various reasons, including global situations and transportation costs, making it difficult to maintain a stable supply.

Shinki Leather Co., Ltd. is now the only company in the world that produces only horse leather and can also produce cordovan leather.

Shinki Hikaku's cordovan is tanned using a method called pit tanning, in which horse hides shipped by sea from Europe are soaked in a pit filled with tannin solution for an extended period of time before being turned into leather.

The tanning agent mainly uses mimosa, and the leather is tanned slowly over a period of several months.

After tanning is complete, the leather must be left to mature in its base state for several months to allow the tanning agent to penetrate deep into the fibers; this is a very important process in producing high-quality cordovan.

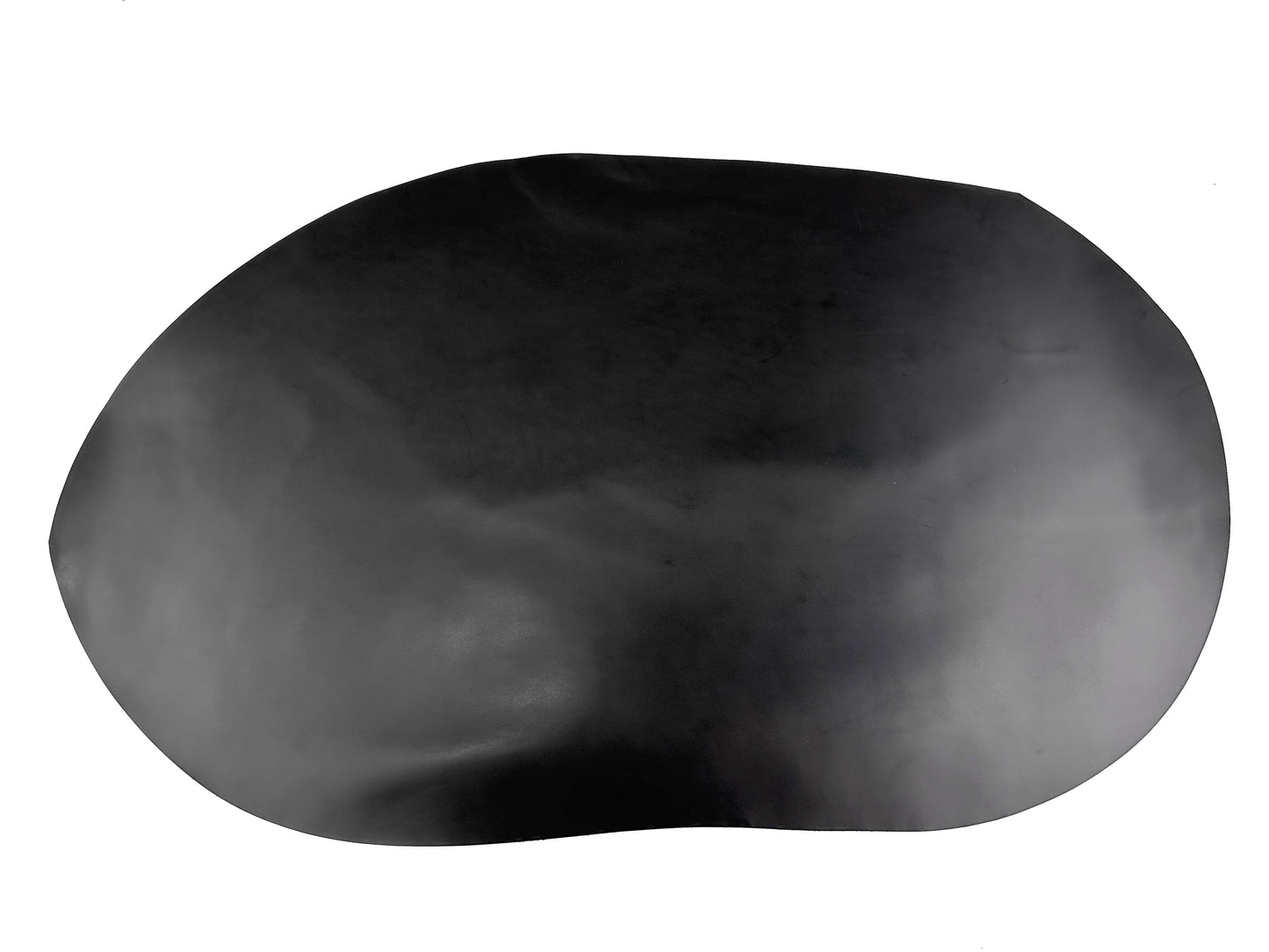

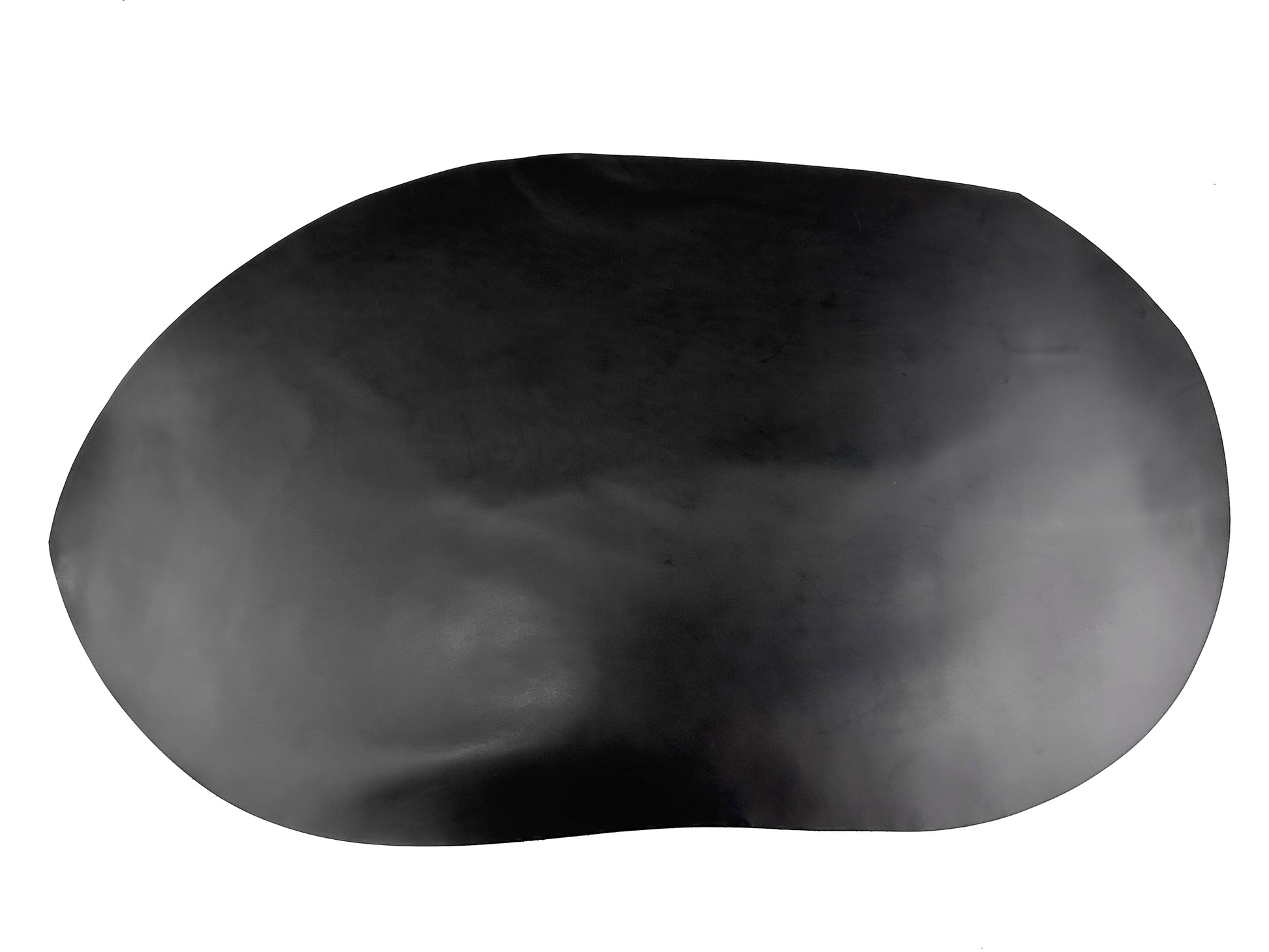

After the aging process is complete, the dense fiber layer found only on the buttocks of a horse, called the cordovan layer, is scraped off from the reverse side of the base material, which is then dyed, finished, and aged again.

From the start of tanning to finishing, it takes approximately 10 months to make oil cordovan.

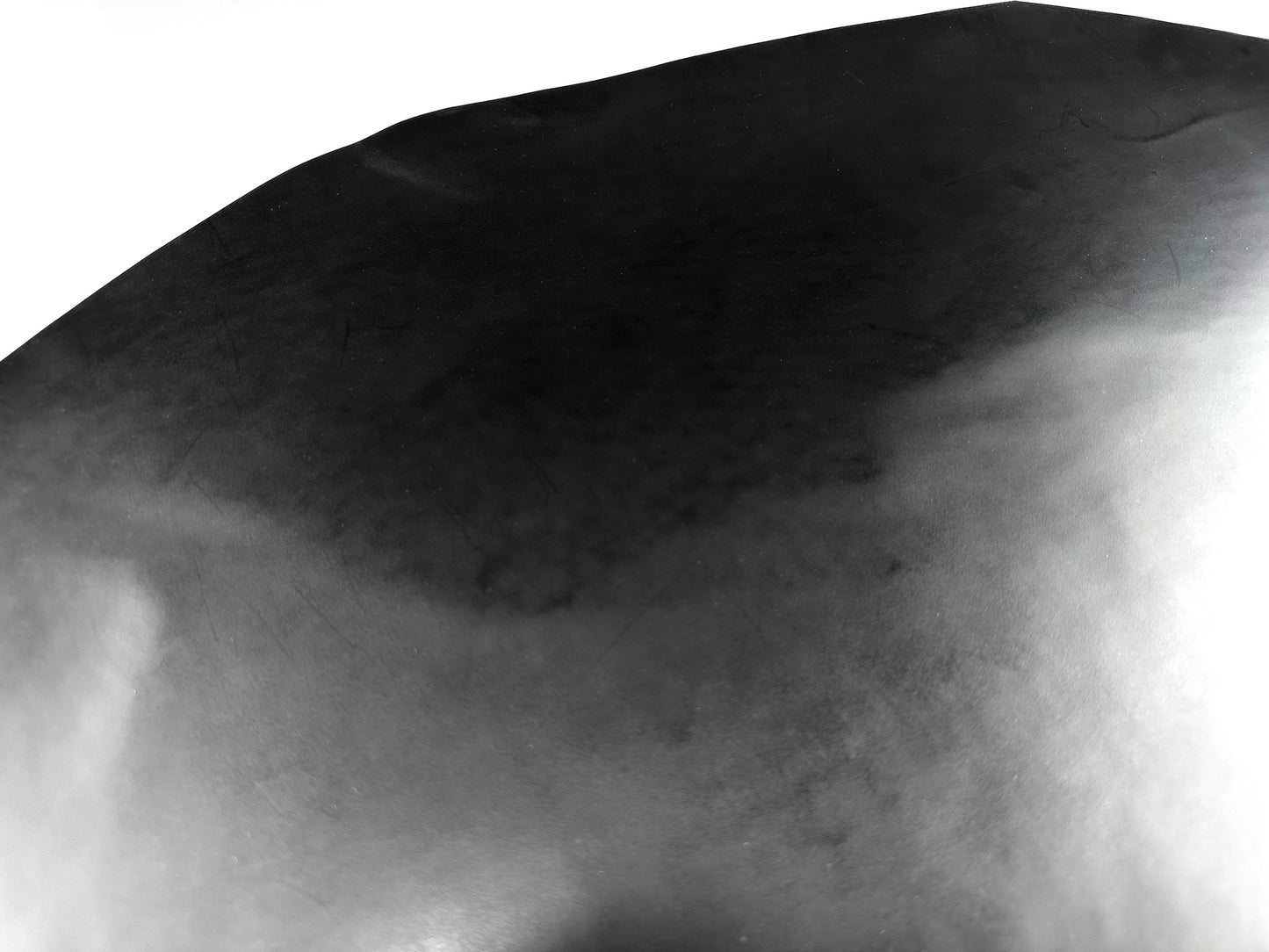

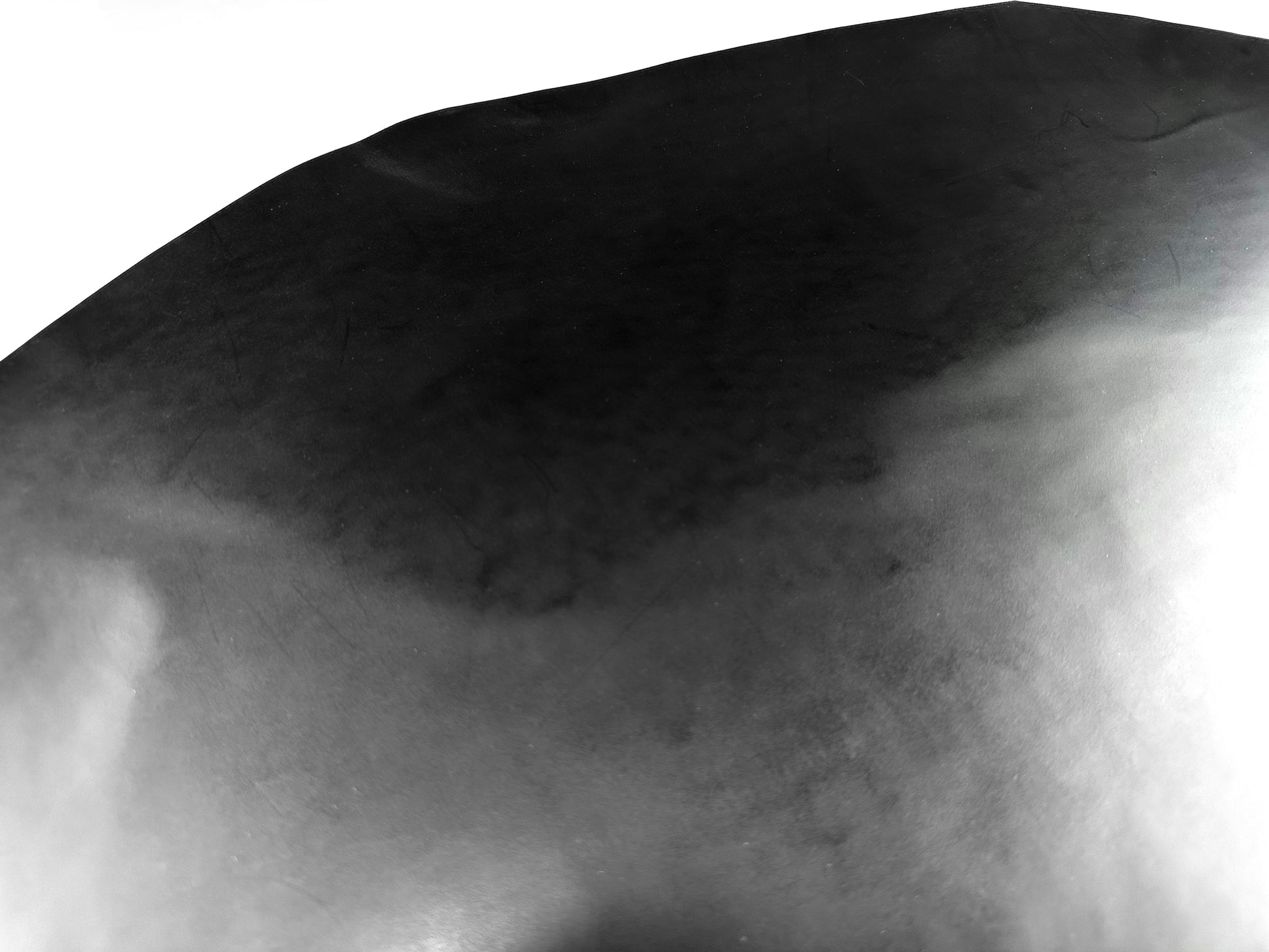

The unique transparency, luster, and depth of color of oiled cordovan is achieved by a process called glazing, in which after the color is mixed with dye, a chemical is applied to the surface of the leather that contains a special oil, and then the leather is rubbed and smoothed using a specialized machine.

This process, which requires adjusting the strength of different parts of a single piece of wood, is a delicate job that requires high craftsmanship and can only be done by hand.

Glazing creates a variety of unique expressions that are unique to cordovan, and no two pieces are exactly the same.

Flexible cordovan developed for shoes

Since its founding, Shinki Leather Co., Ltd. has been researching and honing its technology for over 40 years, and has succeeded in producing and continuing to supply world-class cordovan .

In recent years, the price of horse hides has been rising sharply for various reasons, including global situations and transportation costs, making it difficult to maintain a stable supply.

Shinki Leather Co., Ltd. is now the only company in the world that produces only horse leather and can also produce cordovan leather.

Shinki Hikaku's cordovan is tanned using a method called pit tanning, in which horse hides shipped by sea from Europe are soaked in a pit filled with tannin solution for an extended period of time before being turned into leather.

The tanning agent mainly uses mimosa, and the leather is tanned slowly over a period of several months.

After tanning is complete, the leather must be left to mature in its base state for several months to allow the tanning agent to penetrate deep into the fibers; this is a very important process in producing high-quality cordovan.

After the aging process is complete, the dense fiber layer found only on the buttocks of a horse, called the cordovan layer, is scraped off from the reverse side of the base material, and then dyed, finished, and aged again.

From the start of tanning to finishing, it takes approximately 10 months to make Shin Cordovan.

Shin Cordovan is made by carving out the unique intertwined layers of fibers from a horse's buttocks and finishing with dyes, oils and wax.

Compared to oiled cordovan, it has a more wax and oil coating which means the surface is less likely to become rough when bent, is more resistant to tearing, and has a supple, soft texture that makes it easier to hang.

The smooth, oily texture feels very pleasant to the touch and provides just the right amount of pull.

Although it has a matte finish, you can enjoy the profound aging that is unique to cordovan as you use it.

Since the aniline finish is made using only wax and oil, there is no film on the surface, making it particularly vulnerable to water and easily scratched, so care must be taken when handling it.

Please refer to the official Shinki-Hikaku channel of the manufacturer, Shinki-Hikaku Co., Ltd., for more detailed explanations and care instructions.

* Since horses are creatures that sweat a lot, you may see dot patterns on their surface that are sweat glands.

They are a testament to the intricate fibre layers and surface that are so clearly visible.

* Very delicate surface with dye finish Therefore, please handle it with extreme care.

* Please be careful as the product may get stained or its texture may change if it gets wet.

Japan Eco Leather Gold Tier Products

What is the Japan Eco Leather Certification Program? →Click here for details

If you wish to use the following certificate on your company website or product page, please contact Shinki Leather Co., Ltd.

Unauthorized use is prohibited.

Contact form

Contact form